| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

FINEPLACER®

Hot Air SMD Rework Stations

|  |  |  | |

| FINEPLACER® core | FINEPLACER® coreplus | FINEPLACER® pico rs | FINEPLACER® micro rs | FINEPLACER® jumbo rs |

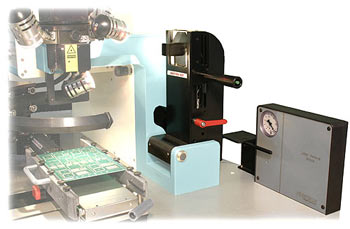

FINEPLACER® Solder Removal Module

The Solder Removal Module allows precise residual solder removal in an inert atmosphere. Molten solder is easily removed from the board with powerful vacuum without disturbing any pads or solder resist.

The software controlled process allows reproducible results. Depending on component size the process can be finished with one single sweep. Also suitable for cleaning BGA interposers before reballing together with reballing module.

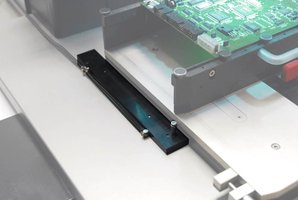

The optional vacuum guide bar is a helpful tool to facilitate the manual site dressing/solder removal process. It prevents an uncontrolled lateral table movement alongs its X-axis while allowing a controlled movement along the Y-axis. Furthermore, the operator can define a mechanical end stop directly at the vacuum guide bar. A small pin will stop the table movement at a certain position during the site dressing process in order to avoid possible damages to adjacent components or pads.

Highlights*

- Contactless solder removal

- Single sweep working principle

- Safe, careful and reproducible cleaning

- Inert gas atmosphere

- Software controlled

- Low thermal load

- Layout specific solder removal head

* depending on configuration

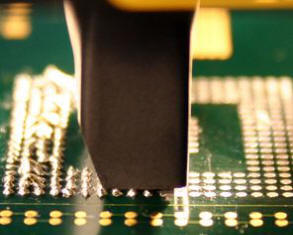

FINEPLACER® Solder Removal Heads

FINEPLACER® Solder removal heads are used in the rework process for removing residual solder after desoldering faulty BGA and CSP. The solder removal head fits into the reflow arm to be heated up by COMISS like a Soldering Head.

Vacuum Rail

An optional vacuum rail provides the user with additional safety requirements for the manual residual solder removal. It prevents unwanted lateral movement along the X-axis and protects surrounding components. Furthermore, the rail is a mechanical end point to move the suction defined on the Y-axis stop.