| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

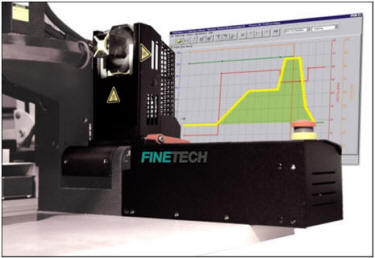

FINEPLACER®

Hot Air SMD Rework Stations

|  |  |  | |

| FINEPLACER® core | FINEPLACER® coreplus | FINEPLACER® pico rs | FINEPLACER® micro rs | FINEPLACER® jumbo rs |

FINEPLACER® Motorized Pivot Arm

The motorized pivot arm for the COMISS hot gas reflow module was introduced to the market, allowing an unrivalled degree of reproducibility in manual rework. The force sensor looks after the touch down force, especially during the time in which the tool “dives” into residual solder.

This way, it is first time possible to compensate thermal warpage of board and component. All movements necessary during the process are controlled by the reflow software WinCOMISS.

After component alignment the process runs without the need of operator intervention. This enhances quality, saves time and thus increases rework throughput.

It goes without saying that older models of the FINEPLACER® series micro, pico and jumbo can be retrofitted with this module.

Highlights

- Automated reflow process

- Controlled contact force adjustable from 0.5 to 15N

- Automatic vacuum control to hold the component and for positioning

- Software-controlled distance from the component (Employment gap for BGA soldering allows free swim)