| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

ONYX Reworkstations for

surface mounted device

ONYX OPTIONS

OPTIONS FOR PROFILE AND TEMPERATURE CONTROL

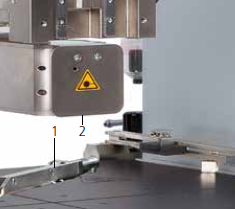

| IR SENSOR 90° (1) This IR temperature measuring Sensor remotely monitors board temperature and provides process control during desoldering or soldering a component. IR SENSOR FIXIED (2) Non-contact temperature mesurement built into the vision system that can be positioned by moving the axis. |  |

| IR SENSOR PIVOTING A manual positioned non-contact IR Sensor that monitors the PCB top side temperature. |  |

| BOARD COOLING Provides specific cooling of the PCB to reduce the cycle time. Different models are available for different size preheaters. |  |

| PYROMETER Uses non-contact, thermal radiation to monitor the temperature during the soldering process using a detection diameter of 1.8mm at a range of 200mm, allowing controlled, reproducible results. |  |

| THERMOCOUPLE MODULE Alle ONYX-Geräte sind mit vier Eingängen für K-Typ Thermoelemente ausgerüstet. Die ONYX 29 kann mit einem Zusatzmodul auf total 8 Thermoelementanschlüsse erweitert werden. |  |

| PREHEATER 300 X 300MM 3500W Preheater with a size of 300x300mm is used as standard on the ONYX 21, 24 & 25. |  |

| TWO-ZONES PREHEATER 245x490MM 3000W (2x1500W) Preheater with a size of 245x490mm. |  |

| FOUR-ZONE PREHEATER 490x490MM Standard equipment on the ONYX 29. 6000W (4x1500W) Preheater with a size of 490x490mm. |  |

| PREHEATER 310x350MM 3260W Preheater with a size of 310x350mm. Supplied as an alternative to the standard preheater on the ONYX 21, 24, 25. Recommended for use multi-layer circuit boards. |  |

OPTIONS FOR COMPONENT / PCB HANDLING

| BRIDGE TRAY The Bridge Tray is used to mount Insertion Tool and Reject Bin, Fluxing accessories and other ancillary equipment. |  |

| ELEVATED BRIDGE TRAY Provides increased above board clearance allowing use of the full area of the preheater. |  |

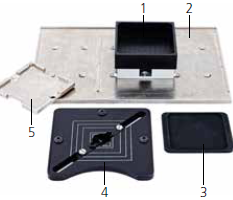

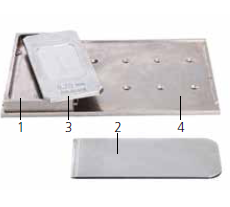

| ADAPTORS AND ACCESSORIES For use with the Bridge Tray, Shuttle or with Nozzle Changer. Various accessories are available. 1 = Component Reject Bin 2 = Tray Plate for Bridge Tray 3 = Adaptor Plate for Nozzle Changer 4 = Insertion Tool 5 = Adaptor Plate for Bridge Tray |  |

| NOZZLE CHANGER A Nozzle Changer can be provided to accommodate different tools or nozzles as part of the automated process cycle. |  |

| PICKUP SHUTTLE AUTOMATIC / MANUAL ONYX 29 Fully automated loading, fluxing or unloading of components. Preparation is completed manually outside of the heated working area. An adjustable Insertion Tool is available in different sizes. Insertion tool 4-45mm, 6-47mm, 9-56mm |  |

| PICKUP SHUTTLE MANUAL ONYX 21, 24, 25 The Pickup Shuttle Manual with an integrated Force Sensor can be used for semi-autmated pickup, dipping or placement of components. An adjustable Insertion Tool is available in different sizes. insertion tool 4-45mm, 6-47mm, 9-56mm |  |

| PICKUP TOOL SWIVELLING Manually positioned under the nozzle, this provides semi-automated pickup of components. |  |

| SECOND BOARD HOLDER Provides an additional working area. This option is available with standard height or additional above board clearence of 20mm. |  |

| BOARD HOLDER EXTENSION Extends the ONYX 21 Board Holder capacity in the Y axis by 100mm. |  |

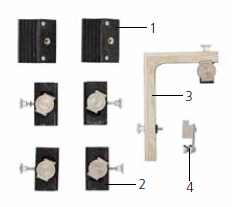

| BOARD HOLDER CLAMPS / FINGERS PCB Holder Clamps, Fingers and End Stop can be used to firmly and accurately locate the PCB in the Board Holder. 1 = Board Holder Clamp - 10mm (2 Stk.) 2 = Borad Holder Clamp ONYX 21(4 Stk.) 3 = Board End Stop (1 Stk.) 4 = Board Holder Finger (1 Stk.) |  |

OPTIONS TO APPLY / REMOVE MEDIA

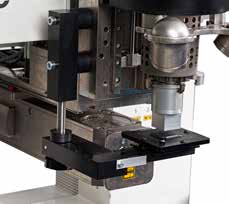

| SITE CLEANING SYSTEM This non-contact Site Cleaning System is used to remove solder and flux residues before placing a new component. This option tracks the board surface using non-contact vacuum control for adjusting the Z height except when installed on the ONYX 21 where the Z height is constant. Various suction tip forms are available on request. |  |

| DIP FLUXER KIT FASET1 Fluxer Kit with a range of fluxer plates for various fluxing applications. |  |

| DIP FLUXER KIT Fluxer Kit with Fluxer Plate Holder and Squeegee. Fluxer Plates with different depths are available on request. Kit contents: 1 = Fluxer Plate Holder 2 = Squeegee Other accessories: 3 = Fluxer Plate (specify depth) 4 = Tray Plate for Bridge Tray |  |

| TIME / PRESSURE DISPENSER To dispense solder paste, flux, adhesive epoxy, underfill or other fluids. |  |

| PASTE ON DEVICE QFN Used to screen solder paste onto the underside of a component. |  |

| REBALLING TOOL For reballing components. With the precision and high level of automation with the ONYX 29 BGA components can be fitted again with solder balls. |  |

| FUME EXTRACTION The Fume Extraction System is mounted to the machine head to collect the fumes emitted during machine processes for extraction by an external filtering system (not included). |  |

| DIRECT VIEW CAMERA Enables real time monitoring of the machine process. The Camera is either on an articulated arm that is table mounted or on a machine mounted holder. An LED light is available. |  |

OPTIONS FOR MACHINE / SOFTWARE

| MACHINE BENCH ESD Machine Benche with ESD surfaces and monitor stands are available for all ONYX models to provide a rigid and stable platform for the machine. |  |

ADVANCED SOFTWARE ACCESS

|  |

| TRACEABILITY LICENSE A Traceability License can be provided for management report documentation and quality control. |  |

ONYX EQUIPMENT

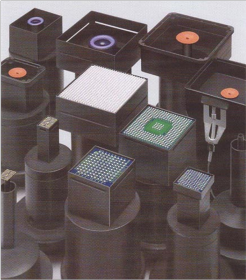

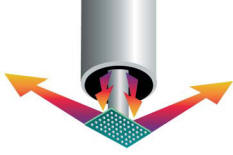

GASNOZZLES FOR SMT COMPONENTS

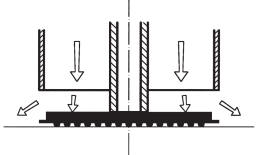

The field of application is selective soldering and desoldering of all commercially available electronic components: simple Chip - capacitor up to SO-ICs, Flat Packs and PLCCs.

Conceived and designed for safe use in the ONYX systems

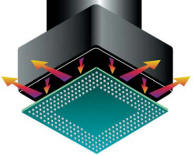

The requirement for high-quality gas nozzles is the safety of the components. The component to be processed and adjacent components must not be endangered by the hot gas and the heated nozzle. Even if PCBs are always more densely populated.

Guaranteeing the highest precision

Modern soldering devices enable a positioning accuracy of ± 0.02 mm. The design, construction and finish of the nozzles should be consistent with this quality level and ensure that even "fine pitch" components can be soldered in and out without risk.

Standard nozzles and special nozzles

Standard nozzles are available for standard components in market-compliant sizes, For non-standardized components, special nozzles are available at short notice.

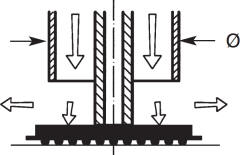

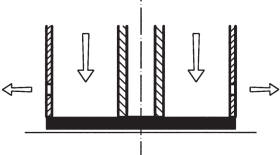

| EZ / EZL GASNOZZLES for PBGA, TBGA, CBGA, SBGA | |

|  |

| Distance to the next component: 0.0mm Vacuum tube is adjustable. | |

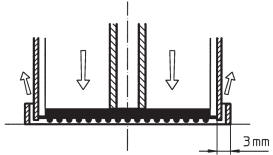

| X GASNOZZLES for PBGA, TBGA, CBGA, CCGA SBGA | |

|  |

| Distance to the next component: min. 3.0mm. Vacuum tube is adjustable. | |

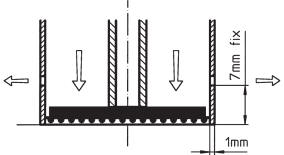

| Y GASNOZZLES for PBGA, TBGA, CBGA, CCGA, SBGA | |

|  |

| Distance to the next component: min. 1.0mm. Vacuum tube is adjustable. | |

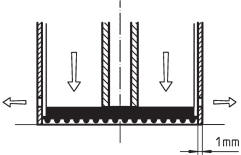

| NS Y GASNOZZLES for μBGA, CSP, Flip Chip | |

|  |

| Distance to the next component: min. 1.0mm. Vacuum tube is adjustable. | |

| DVG GASNOZZLES for μBGA, CSP, Chip 01005, 0201, 0402, ... | |

|  |

| Distance to the next component: 0.0mm. Vacuum tube is adjustable. | |

| NS Y GSH GASNOZZLES for shielding | |

|  |

| Distance to the next component: min. 1.0mm. Vacuum tube is adjustable. | |