| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

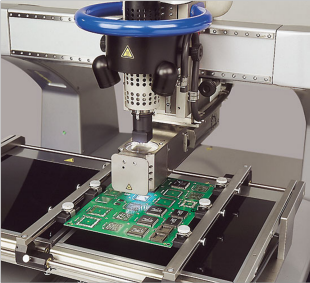

ONYX Reworkstations for

surface mounted device

ONYX 25

SEMI AUTOMATIC SMD SOLDERING

AND DESOLDERING MACHINE

Developed especially for large boards the ONYX 25 offers also force controlled, automated axes movement for a precise positioning and handling of the components.

TECHNICAL DESIGN

The awarded ONYX series combines strong, innovative design both for handling and in construction.

Especially on the ONYX 25 extremely large boards are supported in a firm and stable manner.

BOTTOM PREHEATER

The preheater offers powerful 3500 W and 300x300mm as a standard, with a second module it can be upgraded to 7000 W at 600x300mm.

With this high performance even on large boards the necessary temperature profile can be defined and run to deliver superior results for leadfree.

SITE CLEANING OPTION

By means of the contactless site cleaning option the residue solder after removal of a component is removed without touching or damaging the surface of the printed circuit board.

The site is cleaned and ready for a new component to be soldered in after applying flux or paste.

MOVEABLE SOLDER HEAD

The combination of the open machine construction and the moveable solder head allows free position in x-direction without moving the board.

As the board is kept in position the precise position of components is secured.

For fast movement and for quick positioning over the rework area.

VISION SYSTEM

As a standard on all rework machines of the ONYX series an advanced MFOV Vision System allows to see components as large as 75 x 75mm, as well as small as 0.3 mm.

FORCE MEASUREMENT SYSTEM

Also as a standard on all ONYX rework machines the force measuring system is used for placement to protect sensitive components.

REPEATABLE, PRECISE AUTOMATION

The in house build machine software VISUAL MACHINES is the basis for fast and flexible profile definition.

The profiles stored in the library and the features of the machine guarantee repeatable, precise selective soldering and desoldering results.

LEAD FREE SOLDERING

All ONYX machines come with a nitrogen connection as a standard.

This possibility, the high performance top side heating 2000W and bottom side heating 3500W (7000W) deliver the basic to assure reliable soldering results including leadfree.

|  |

ONYX 25 KEY FEATURES SUMMARY

- AXIS MOVEMENTS

4 motorised axis, closed loop motion control - LARGE BOARD HANDLING

for boards up to 520 mm width, no limitation for length thanks to open construction - STRONG TOP AND BOTTOM HEATING

2000 W top site heater; 3500 W 300x300mm bottom side preheating per module (max. 2) - UP TO 8 THERMOCOUPLE PORTS

to control process temperatures - AUTOMATIC SITE SOLDER CLEANING SYSTEM

option for site cleaning after removal of component - CLOSED LOOP AIRFLOW CONTROL

- STANDARD GAS NOZZLES

- BOARD CARRIER

handles irregular-shaped assemblies without special fixturing - FORCE MEASUREMENT

Closed loop force control for automatic picking, fluxing, placing and removing - VISION

New MFOV Vision System allows viewing of component up to 75x75mm, Adjustable Vision LED illumination intensity

| Technical data | |

| Product designation | ONYX 25 |

| Max. board size | 560mm width, depth unlimited |

| Max. component height | 20mm bottom side (optional 30mm) 30mm top side (optional 70mm) |

| Max. component size | 70 x 70mm |

| Gas pressure | 4-6bar |

| Angle rotation of heater head | ± 10° |

| Hot gas | compressed air or nitrogen, 20-80l/min |

| Power requirements | 3 x 400/230VAC, 50/60Hz |

| Max. power consumption | 6400W (+ 3500W per add. preheater module) |

| Dimensions (W x D x H) | 898 x 1050 x 1022mm |

| Weight | 150 kg (basic machine) |

Module und Optionen

- IR-Sensor

- Board cooling

- 2nd preheater 300 x 300mm

- Component pick up tool

- Fume extraction

- Site Solder Removal System

- Direct View Camera System

- Machine base