| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

ONYX Reworkstations for

surface mounted device

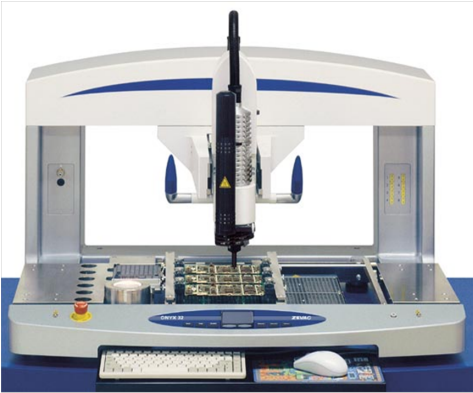

ONYX 32

MULTIFUNCTIONAL POSITIONING

AND SOLDERING SYSTEM

The ONYX 32 offers the highest degree of automation out of the ONYX series.

Between loading and unloading of the substrates and component feeders the process is executed fully automated.

The platform can be equipped for all variations of automated hot gas rework processes.

TECHNICAL DESIGN

Fully automatic high performance unit with digital vision system for highest precision in rework and positioning applications.

The open platform is dedicated for serial rework as well as for prototype and small series production.

The system complies with quality requirements that are commonly used in electronics production.

FLEXIBILITY, RELIABILITY AND PRECISION

A cartesian 4-axis robot system with linear motion as base platform combined

with a wide range of application specific options allow flexibility without

forgoing process reliability and precision within micron range.

PROCESS VARIETY

Absolute and relative placement according to CAD placement data, component

handling, dipping, stamping, fluxing, dispensing, odd shape recognition,

inspection, height measurement, soldering, heating, curing, cooling.

APPLICATION

For fully automated rework processes of SMD components, shieldings and connectors.

Desoldering, site cleaning, fluxing, placement and soldering is done without operator intervention.

|  |

ONYX 32 KEY FEATURES SUMMARY

- AXIS MOVEMENTS

4 motorised axis, closed loop motion control - INTEGRATED VISION SYSTEM

for automatic component alignment and any shape recognition such as

fiducials, bar code, data matrix, component outlines or land pattern - HOT GAS NOZZLE CHANGER

for an automatic change of up to six nozzles - ASSEMBLY TOOL CHANGER

allows the use of up to six different pick & place tips, micro-stencils,

die-collets or pin print transfer tools - LIQUIDS DISPENSER

applies any liquids such as flux, adhesives, solderpaste to the substrate.

Flexible line and dot pattern definition - TOUCH PROBES

to align nozzle, tool and needle length. Compensates loss of accuracy

caused by board warpage and buckling - STRONG TOP AND BOTTOM HEATING

2000W top heater; 4000W bottom preheating - AUTOMATIC SITE SOLDER CLEANING SYSTEM

option for site redressing after removal of component

| TECHNICAL DATA | |||

| ONYX 32 with Hot Gas Soldering System and Preheater | |||

| Electrical power | at machine table | 100–240 VAC 50/60Hz | |

| Board- | Minimum | 20 x 20mm | |

| dimensions | Maximum | 355 x 320mm | |

| With manual rotation | 355 x 680mm | ||

| Max. camera field of view | 355 x 250mm | ||

| Preheater heating area | 355 x 290mm | ||

| Max. component height | Top side | 60mm | |

| Bottom side | 20mm | ||

| X | Y | Z | Theta | |

| Axes acceleration | 0,75 ms-2 | 0,75 ms-2 | 0,75 ms-2 | 4 rots-2 |

| Axes speed | 0,15 ms-1 | 0,15 ms-1 | 0,25 ms-1 | 0,8 rots-1 |

| Working area | 500mm | 320mm | 80mm | ∞ |

| Axes resolution | 0,001mm | 0,001mm | 0,0015mm | 0,003°mm |

| Placement accuracy bei +/– 3 Sigma | +/–0,02mm | +/–0,02mm | +/–0,02mm | +/–0,02mm |

| Digital color cameras | Resolution | 640 x 480 pixels |

| Hot Gas Soldering System | Max. temperature | 400ºC |

| Max. flow rate | 85 l/min | |

| Preheater | Max. constant temp. | 300ºC |

| Force sensor in Z direction | Force area Resolution | 1 - 30N 0.1N |

| Machine table 3 x 400VAC 3PNE | ||

| acc. CE safety regulations | 3 x 400VAC, 3-phasig Fuse value | 50Hz 3 x 16A |

| Machine table 3 x 208VAC 3PE | ||

| acc. UL safety regulations | 3 x 208VAC, 3-phasig Fuse value | 50/60Hz 3 x 20A |

| Options | ||

| Conductive Heat Soldering System | Max. temperature Max. component size | 400ºC 25.4 x 25.4mm |

| Liquids Dispenser | Smallest dot Placement accuracy | Ø 0.25mm ±0.05mm |

| Site Solder Removal System | Vacuum value Vacuum flow rate | 500mbar 80l/min |

| Dimensions (WxDxH) | 910 x 857 x 702 | |

| Machine table (WxDxH) | 1800 x 800 x 670/720 | |

| Weights | ONYX 32= 135kg | Machine table= 90kg |

Moduls and Options

- Conductive Heat Soldering System

- Liquids Dispenser

- Site Solder Removal System