| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

ONYX Reworkstations for

surface mounted device

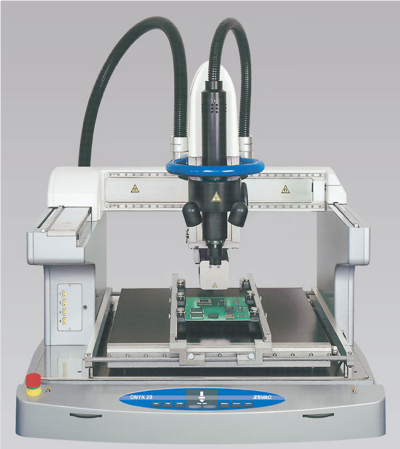

ONYX 29

SEMI-AUTOMATED SMD SOLDERING

AND DESOLDERING MACHINE

The ONYX 29 machine precision, automatic processes and easy operation have been the basics for the development of this new platform.

TECHNICAL DESIGN

The machine design follows the one of the multifunctional platform ONYX 32.

The open and user friendly design of the ONYX 32 has been awarded with the Good Design Award in 2002.

In the ONYX 29, this open construction supports the motorised X, Y, Z and Vision movements, whereby 2 axes are equipped with linear motors enabling optimized and smart motions for the applications.

BOTTOM PREHEATER

The powerful, large 4 zones bottom preheater for large printed circuit boards has an active zone of 400 x 400mm.

MFOV (multiple field of view) VISIONSYSTEM

advanced MFOV Vision System allows to see components as large as 75 x 75mm.

FORCE MEASUREMENT SYSTEM

Beneath other parameters, the force measuring system is used for placement to protect sensitive components and allows process automation.

SELECTIVE AUTOMATION

Defined process parts can be executed fully automatic.

This guarantees the soldering results but also helps the operators to execute repeatable and controlled processes.

The programmed software parameters automatically control the desoldering program, the placement and the soldering program.

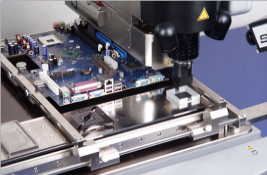

SITE SOLDER REMOVAL SYSTEM

Especially for the rework of BGA's, the fully automatic Site Solder Removal System is an important feature.

SPECIAL SOFTWARE

The ONYX 29 profits by the in-house developed software, a strong and modern software to support the operator with an easy-to-use surface and to make complex features for today's and tomorrow's applications available to the machine.

LEAD FREE SOLDERING

The basic ONYX 29 is outlined for lead free soldering already.

The use of the respective materials and a 2000W top and 6000W bottom heating together with the nitrogen input assure reliable and reproducible thermo profiles and soldering results to meet the increasing needs of the electronic industry.

WIDE APPLICATION RANGE

Not only options to the ONYX 29 complete the basic unit, also existing DRS gas nozzles can be used.

So applications for all existing SMD components like 0201, CSP, BGA, Flip Chip, LGA, connectors shiledings or special components can be done

with the ONYX 29.

|  |

ONYX 29 KEY FEATURES SUMMARY

- AXIS MOVEMENTS

All 7 axis motorised, closed loop motion control - MANUALMOTION

via integrated hand wheels - PC

With Windows based software - UP TO 8 THERMOCOUPLE PORTS

to control process temperatures - AUTOMATIC SITE SOLDER CLEANING SYSTEM

with motorised X/Y/Z-System - CLOSED LOOP AIRFLOW CONTROL

8 to 80 l/min. using a massflow controller - STANDARD GAS NOZZLES

- BOARD CARRIER

handles irregular-shaped assemblies without special fixturing - FORCE MEASUREMENT

Closed loop force control for automatic picking, fluxing, placing and removing - VISION

New MFOV Vision System allows viewing of component up to 75x75mm,

Adjustable Vision LED illumination intensity

| Technical data | |

| Product designation | ONYX 29 |

| Max. board size (W x D) | 500 x 500mm (longer on demand) |

| Robot working area | 400 x 400mm |

| Board thickness range | 6mm |

| Vision system object size | 0,2 x 0,2mm - 70 x 70mm |

| Max. component height | 20mm bottom side (30mm optional) 30mm top side (70mm optional) |

| Component and board illumination | adjustable LED lights |

| Top heater power | 2000W |

| Hot gas flow range | 8 - 80 l/min (closed loop controlled flow) |

| Preheater system | 4 independent zones of 1500W each heated size: 490 x 490mm |

| Input pressure | 4 - 6bar |

| Temperature range | 20°C - 475°C |

| Hot gas | air or nitrogen |

| Cooling gas | heater element by-pass pneumatic system (closed loop controlled flow) |

| Controller | computer controlled, Windows XP VisualMachinesTM GUI |

| Power requirements | 3 x 400/230VAC, 3PNE, 16A, 50/60Hz |

| Dimensions (W x D x H) | 823 x 821 x 951mm |

| Weight | 140 kg |

Optionen

- Non contact site solder removal system

- Non contact temperature sensor

- Dispenser

- Direct view camera system

- Component pick up holder

- Board cooling system

- Fume extraction