| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

Fume- Gas- and Dust- Extraction Systems

Dgital Extraction System

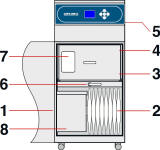

9000-400i-Condensor

|

|

High Performance Fume Extractor for Dye Sublimation Printers

Construction:

Precision engineered brushed stainless steel units.

High performance continuous run brushless motors.

Mounted on castors for mobility.

For sublimation processes in which glycol vapors of this exhaust system was equipped with a condenser unit that receives the vapors before they load the filter system.

A drain valve allows you to drain the condensed liquid.

Digital Control System

A dedicated control, monitoring and display system unique to Purex fume extractors.

All functions are fully automatic, all the user has to do is set the appropriate airflow on installation.

The features of this system are designed to:

- Lower energy consumption by using variable speed motors and automatic flow control

- Increase filter life by using the optimal extraction rate

- Further protect people by constantly monitoring exhaust emissions

- Interface with other equipment e.g. a laser

- Maintain a constant extraction rate to prevent fume escape or damage to equipment.

In the case that in the process the generation of large quantities of particles, in addition, the installation of an Inline-filter is recommended.

Features

- Automatic electronic flow control - maintains a constant extraction rate even as the filter blocks

- Adjustable airflow

- Clear and informative graphic display

- Gas and Particle Sensors on the exhaust

- Low capital and running costs

- Quick change patented Labyrinth pre-filters deliver longer filter life

- Submicronic (HEPA) filtration removes 99.997% of particles down to 0.3 microns

- Activated carbon filtration removes harmful gas

- Liquid condensor unit and drain point

- Simple to install and quiet in operation

- Easy to relocate and precision made from stainless steel

- Optional: Machine Interfacing

- Start/Stop Control: Extraction unit starts/stops when a connected piece of equipment is switched ON/OFF

- Filter Blocked Warning: A signal is sent to a connected piece of equipment to trigger an alert or to shut it down

- Remote ON/OFF Switch: 5M cable & switch

| 400i-condensor standard filters | ||

| Filter typ | Filter description | Code |

| Main filter | HEPA/Activated carbon | 113.505 |

| Pre filter | Labyrinth F8/F9 Composite | 111.097 |

| Pre filter | Pad F5 | 202.260 |

| Technical specifications | 400i-Condensor |

| Part number | 103.086.OLX.402 |

| Voltage | 230V ±10% |

| Wattage | 1,3kW |

| Frequency | 50/60Hz |

| Sound rating | 52dBA |

| Flowrate (max) | 400m³/h |

| Vaccum (max) | 9,92kPa |

| Dimesions wxdxh | 465x528x1070mm |

| Weight (incl. filters) | 60kg |

| Hose connection Ø | 80mm |