| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

FINEPLACER®

Hot Air SMD Rework Stations

|  |  |  | |

| FINEPLACER® core | FINEPLACER® coreplus | FINEPLACER® pico rs | FINEPLACER® micro rs | FINEPLACER® jumbo rs |

FINEPLACER® Bottom Heating Module

The heat source of the Bottom Heating Module provides heat transfer via inert gas or air. The wide variety of heaters ensures an appropriate solution for various applications. Finetech's approach replaces excessive electrical power application by efficient use of energy.

Bottom Heating Modules are part of the Integrated Process Management system (IPM) which offers software-controlled interaction of top and bottom heating. IPM provides one profile for the entire thermal management of every rework step. The result is minimized thermal load to board and component and a maximum of process reproducibility.

All bottom heaters can be adapted to different board sizes.

FINEPLACER® Bottom Heating Module

RB07

Highlights*

- Even heat distribution

- Precise board temperature control

- Reproducible soldering profiles

- Specific heating and cooling profiles

- Supports dynamic ramp rates

- Controlled active cooling function meets JEDEC/IPC standards

- Preheating capabilities

- Lead-free approved

- Adaptable for various PCB sizes

* depending on configuration

| Technical Specifications | |

| Power (max) | 900W |

| Gas temperature (max) | 360°C |

| Flow range | 16 - 80Nl/min |

| Flow resolution | 8Nl/min |

| Ramp rate | 1 - 20 K/s |

| Ramp resolution | 1K/s |

| Heated area (max)1 | 12 x 12mm |

| Number of heating zones | 1 |

| Optional diffusors | |

| Heated area (max)2 | 50 x 50mm |

| Heated area (max)2 | 50 x 100mm |

| Heated area (max)2 | 100 x 100mm |

| 1 Diffusor included 2 Optional available |

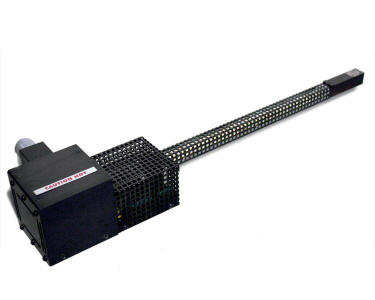

FINEPLACER® Bottom Heating Module

RB11

Highlights

- Even heat distribution

- Precise board temperature control

- Reproducible soldering profiles

- Specific heating and cooling profiles

- Supports dynamic ramp rates

- Controlled active cooling function meets JEDEC/IPC standards

- Preheating capabilities

- Lead-free approved

- Adaptable for various PCB sizes

For machining small circuit boards, the use of an intermediate adapter, in the air-cushion table is required.

| Technical Specifications | |

| Power (max) | 1600W |

| Gas temperature (max) | 360°C |

| Flow range | 32 - 160Nl/min |

| Flow resolution | 16Nl/min |

| Ramp rate | 1 - 10 K/s |

| Ramp resolution | 1K/s |

| Heated area (max) | 280 x 250mm |

| Heated area (min) | 280 x 100mm |

| Number of heating zones | 1 |

FINEPLACER® Bottom Heating Module

RB20

similar picture

Flexieble and Powerful hot air Pre-heater for heating and cooling over the entire surface of medium-sized to very large circuit boards with high thermal requirements.

Highlights

- Segmented system

- Clamping system for large PCBs

- equal heat distribution

- Precise control of the board temperature

- reproducible soldering profiles

- Specific heating and cooling ramps allow rapid temperature changes

- Controlled active cooling function meets JEDEC/IPC standards

- Preheating capabilities

- Lead-free approved

- Adaptable for various PCB sizes

| Technical Specifications | |

| Power: | |

| Segment 1 | 350W |

| Segment 1+2 | 1050W |

| Segment 1-3 | 2100W |

| Heated areas: | |

| Board size (max) | 420 x 380mm |

| Segment 1 | 190 x 95mm |

| Segment 1+2 | 190 x 284mm |

| Segment 1-3 | 285 x 380mm |

| Gas temperature (max) | 320˚C |

| Flow range | 10 - 96Nl/min |

| Flow resolution | 16Nl/min |

| Ramp rate | 1 - 10K/sek |

| Ramp resolution | 1K/sek |

| Number of heating zones | 6 |

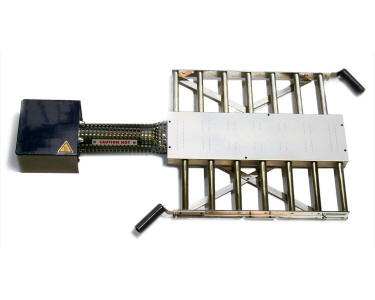

FINEPLACER® Bottom Heating Module

RB15

Flexieble and Powerful hot air Pre-heater for heating and cooling over the entire surface of medium-sized to very large circuit boards with high thermal requirements.

Highlights

- Segmented system

- Clamping system for large PCBs

- equal heat distribution

- Precise control of the board temperature

- reproducible soldering profiles

- Specific heating and cooling ramps allow rapid temperature changes

- Controlled active cooling function meets JEDEC/IPC standards

- Preheating capabilities

- Lead-free approved

- Adaptable for various PCB sizes

| Technical Specifications | |

| Power: | |

| Segment 1 | 350W |

| Segment 1+2 | 1050W |

| Segment 1-3 | 2100W |

| Segment 1-4 | 3500W |

| Heated areas: | |

| Board size (max) | 420 x 380mm |

| Segment 1 | 190 x 95mm |

| Segment 1+2 | 190 x 284mm |

| Segment 1-3 | 285 x 380mm |

| Segment 1-4 | 475 x 380mm |

| Gas temperature (max) | 320˚C |

| Flow range | 10 - 160Nl/min |

| Flow resolution | 16Nl/min |

| Ramp rate | 1 - 10K/sek |

| Ramp resolution | 1K/sek |

| Number of heating zones | 10 |

FINEPLACER® Process Start Sensor

Reproducing all relevant process parameters is imperative for consistently flawless results. The Start Sensor measures the temperature of a defined point on the board surface.

As soon as the board surface reaches an adjustable threshold, the reflow process will start automatically.This way, an accurate process is guaranteed, independent of the board's initial temperature. The PCB is only exposed to as much heat as necessary - this reduces thermal stress and process time significantly.

The start sensor is optionally available for the top heating module.

Highlights*

- Precise contactless measurement

- No in-process handling required

- Free positioning of measuring spot

- Software controlled emission value (factor) and offset

* depending on system and configuration

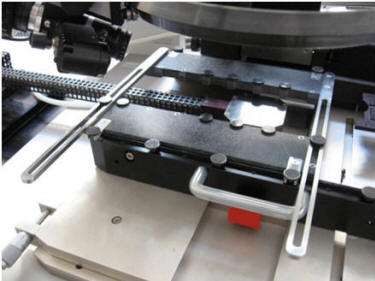

FINEPLACER® Adapter for small pcb

For the machining of printed circuit boards of size <100mm, is clamped into the positioning table an intermediate adapter which can be moved together to 0mm.

The intermediate adapter can be used at the bottom heating modules RB11.