| Phone: +49(0) 5691-6287-0 | ||

| Fax: +49(0) 5691-6287-29 | |||

| Contact: mailto: JOERNS GmbH |

Fume- Gas- and Dust- Extraction Systems

Filtration

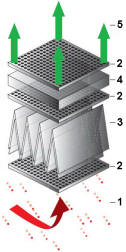

Suction direction is from bottom to top (not FumeCube / FumeBuster).

Through the 90 ° reverse flow heavy particles sink down and deposits on the main filter can be prevented.

The standard main filters are equipped with a HEPA part and treated activated carbon, e.g. to neutralize acid flux fumes or unwholesome gases.

Patented Labyrinth™ bag prefilter offer a high capacity to collect particles and allows her long life.

System- and Filter configuration can be adapted to the needs and requirements of the application.

JOERNS GmbH was the first company which established a full recycle-management for used filters. As most filters will contain hazardous material especially when laser were involved, (if for example PVC is lasered, acid will be produced), the filters have to be disposed by legal companies, who follow special laws. All our filters have an own serialno. and are noticed by JOERNS GmbH from the delivery-date till the feedback from the disposal-company.

JOERNS GmbH will take back Main and pre-filter after use and a waste disposal company for proper disposal fed (hazardous waste) will disposal the filters. A proof of the legal disposal than will send to your environmental management. JOERN GmbH will take back the used filters after JOERNS GmbH has been informed that the filters are ready to be collected.

|

|

Filter stage 1

Labyrinth™ bag pre-filters

| Extends the life of the main filter by capturing larger particles before they reach the HEPA filter. |  |

| There are two possibilities to use Labyrinth™ bag pre-filters: | |

| |

| Bag-filters collect the particles only in the filter-material and not in the space between the walls. This is different from the collecting-method of vacuum cleaners. | |

| Ideal for medium-high volume applications. | |

| Can deal with sticky or moisture laden particles. | |

| Composite material available for extra filter life and filtration down to 0.5 micron. | |

| Contains the particles inside for clean and simple disposal. | |

| For units serving the pure Fume and thus do not require a bag filter, a prefilter plate is used in the main filter. It consists of a flow of two different densities. |  |

Filter stage 2

HEPA* filter in submicron range

| In the main filter reinforced comes not bursting materials for use to remove the smallest particles from the air stream. |  *High Efficiency Particulate Airfilter | |||||

| HEPA filters remove 99.997% of all particles above 0.3 µm and 95% down to 0.01 µm. | ||||||

| ||||||

The standard filter has a surface area of 4.03 m². | ||||||

| Standard main filter are designed as combination with H14 HEPA filter and activated carbon in some part and serve to receive particulate matter as well as the neutralization of vapors and gases. | ||||||

| The housings off all filters are made of galvanized sheet steel and guaranty sealed stability. |

Filter stage 3

Activated carbon filter

| An efficient active carbon layer in the main filter adsorbs toxic gases before the clean air is returned to the workplace. |  |

| Available are simply activated- and double activated carbon. | |

| Depending on the nature of the resulting process gases, a specially treated activated carbon is offered. | |

| Standard main filter are designed as combination with H14 HEPA filter and activated carbon in some part and serve to receive particulate matter as well as the neutralization of vapors and gases. | |

| The standard filter #113.505 has an activated carbon range of 7kg. | |

| The housings are made of galvanized sheet steel. |